Advanced Microscopy

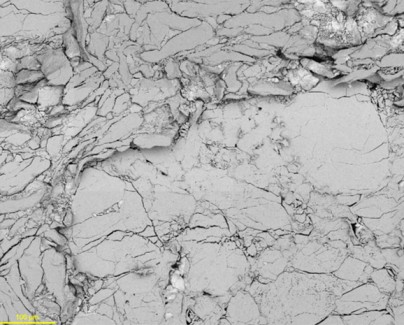

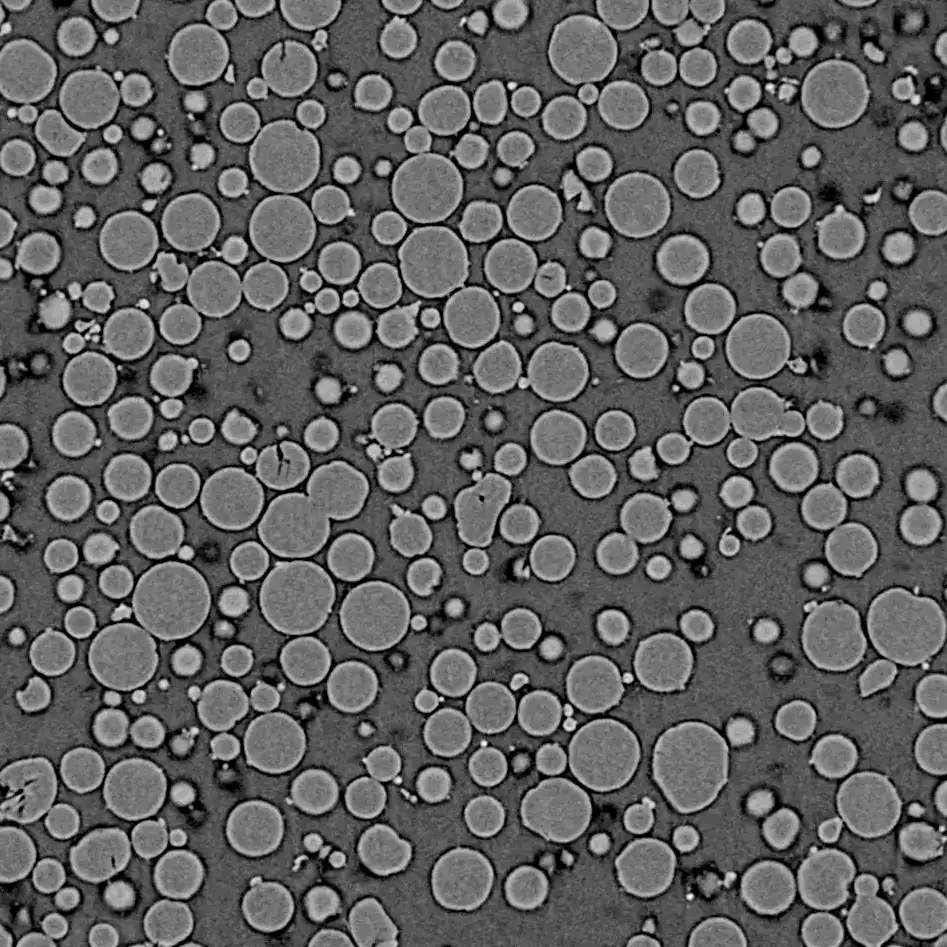

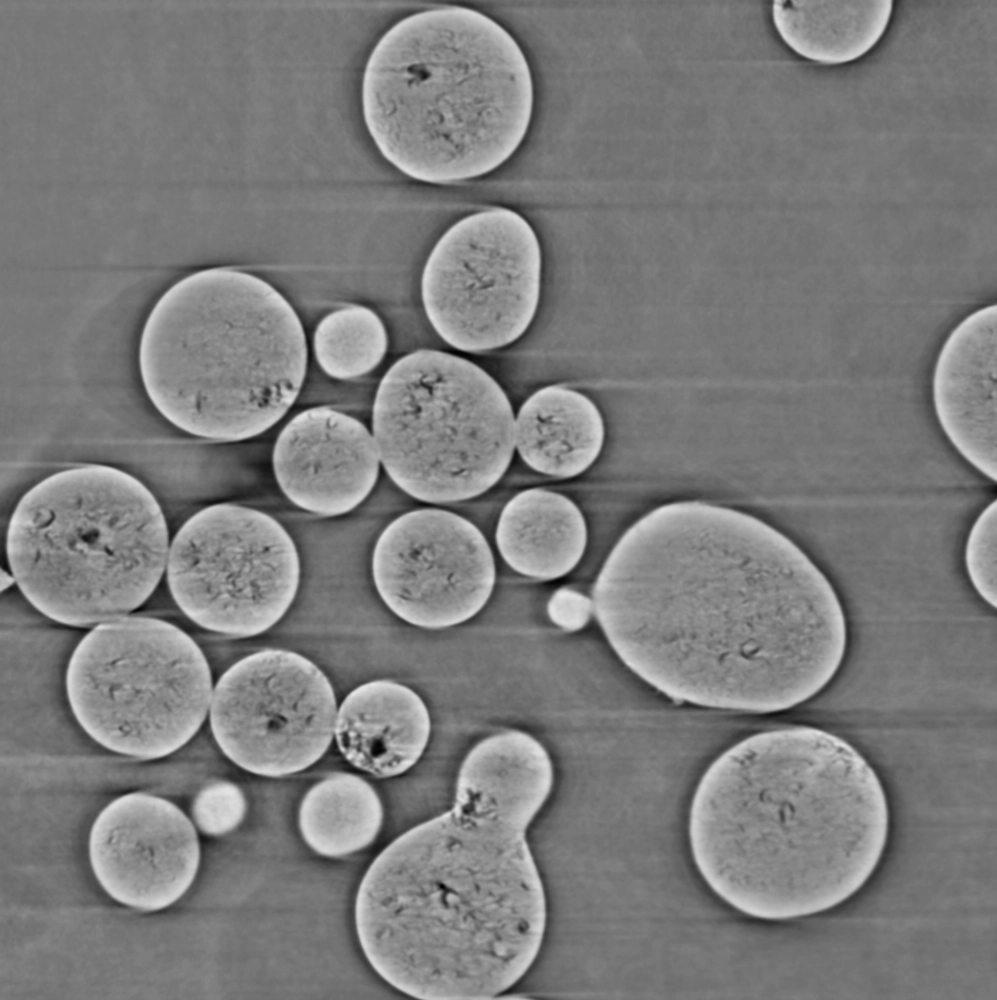

We use a correlative approach to microstructure analysis with microscopies at different scales for accurate and representative quantification.

Advanced Microscopy

Advanced Microscopy

Our process

Advanced Microscopies

Our process

View Additional Services

Transform Your Program with Microstructure Science

Get started with a drug product digital twin.