X-ray micro-CT

X-ray Micro-Computed Tomography is a technique for non-destructive 3D imaging, typically targeting 0.5 to 50 micron resolution.

What is X-ray micro-CT?

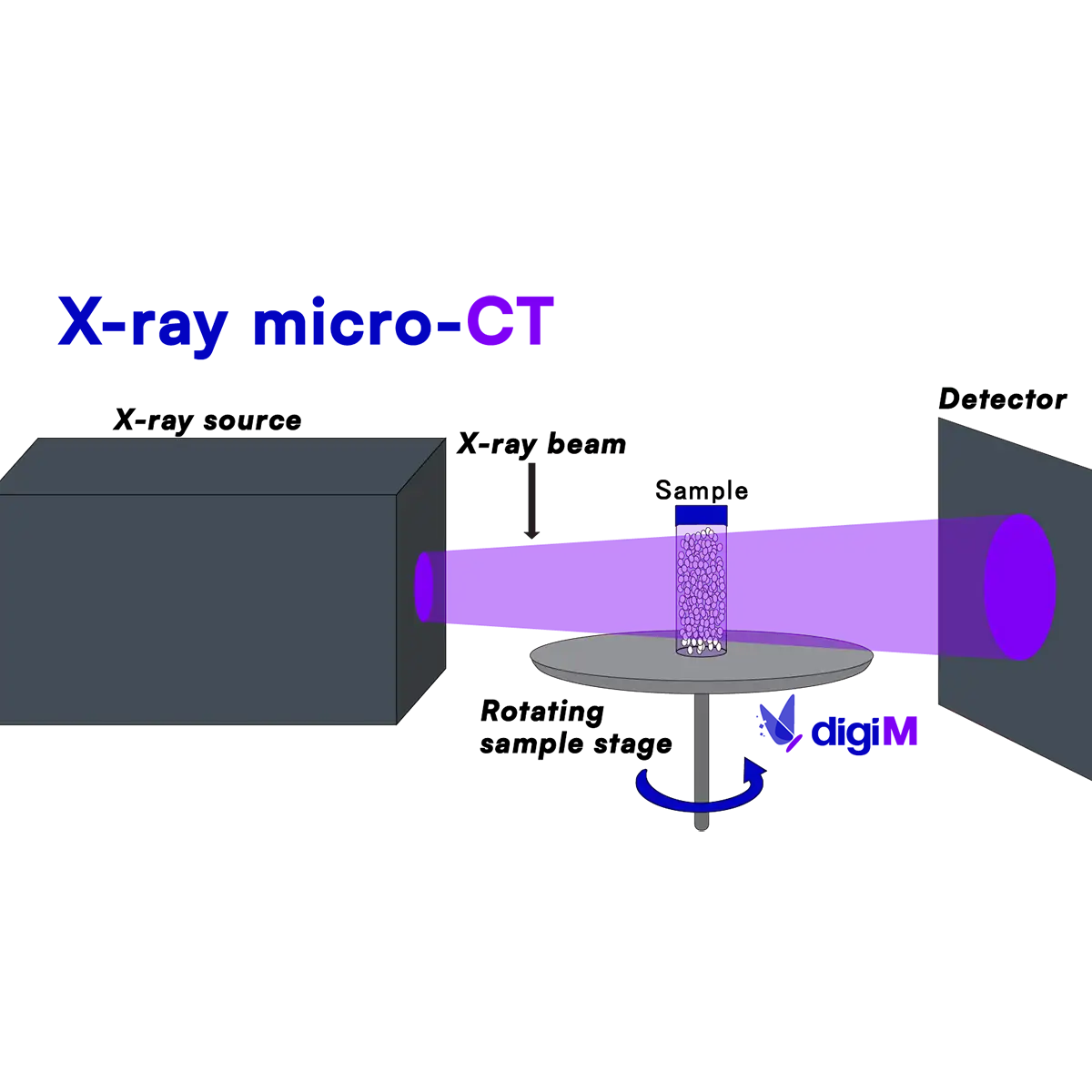

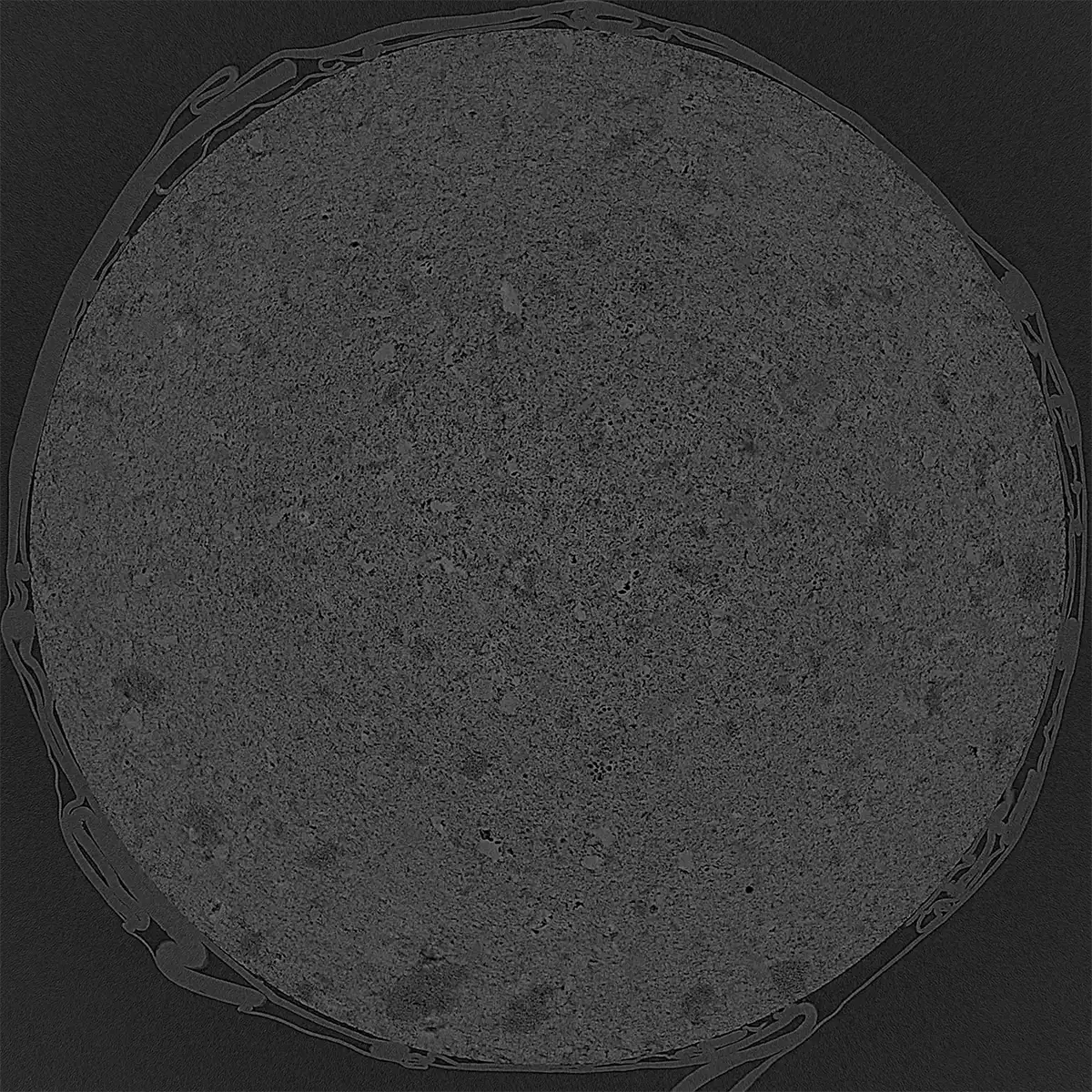

X-ray micro-CT (XRCT) is a non-destructive technique which employs an X-ray source and computed tomography to collect a 3D scan of an object. Similar to a CT CAT scan, the sample sits on top of a stage which rotates after each image is collected, and these hundreds of images are then reconstructed into a 3D volume of the sample. X-ray micro-CT technologies are highly adaptable in field of view, enabling inspection of both macroscopic and microscopic features. For XRCT, the contrast of material domains depends on relative X-ray attenuation, with contributions from their true density and elemental composition. There are both lab-based and synchrotron X-ray micro-CT systems, the latter of which enables improved data quality through the use of a higher energy, monochromatic X-ray source. XRCT scan resolutions can range from 10s of nanometers to 100s of microns. We often complement our XRCT studies with FIB-SEM and mosaic-SEM analysis for a more detailed investigation of structures.

End-to-end micro-CT analysis services

Any XRCT experiment requires careful consideration around the feature sizes of interest, the resolutions needed to resolve features, the expected contrast between material domains, and the field of view ideal to study. Through decades of experience, we’ve mastered routine collection of micro-CT datasets, ensuring high data quality and accurate inspection for the features of interest. Our X-ray micro-CT services include the whole suite of analysis, from dataset collection to image processing, structure analytics, and image-based modeling. To account for samples and features of different sizes, we use an array of different XRCT systems.

micro-CT analysis for drug product development

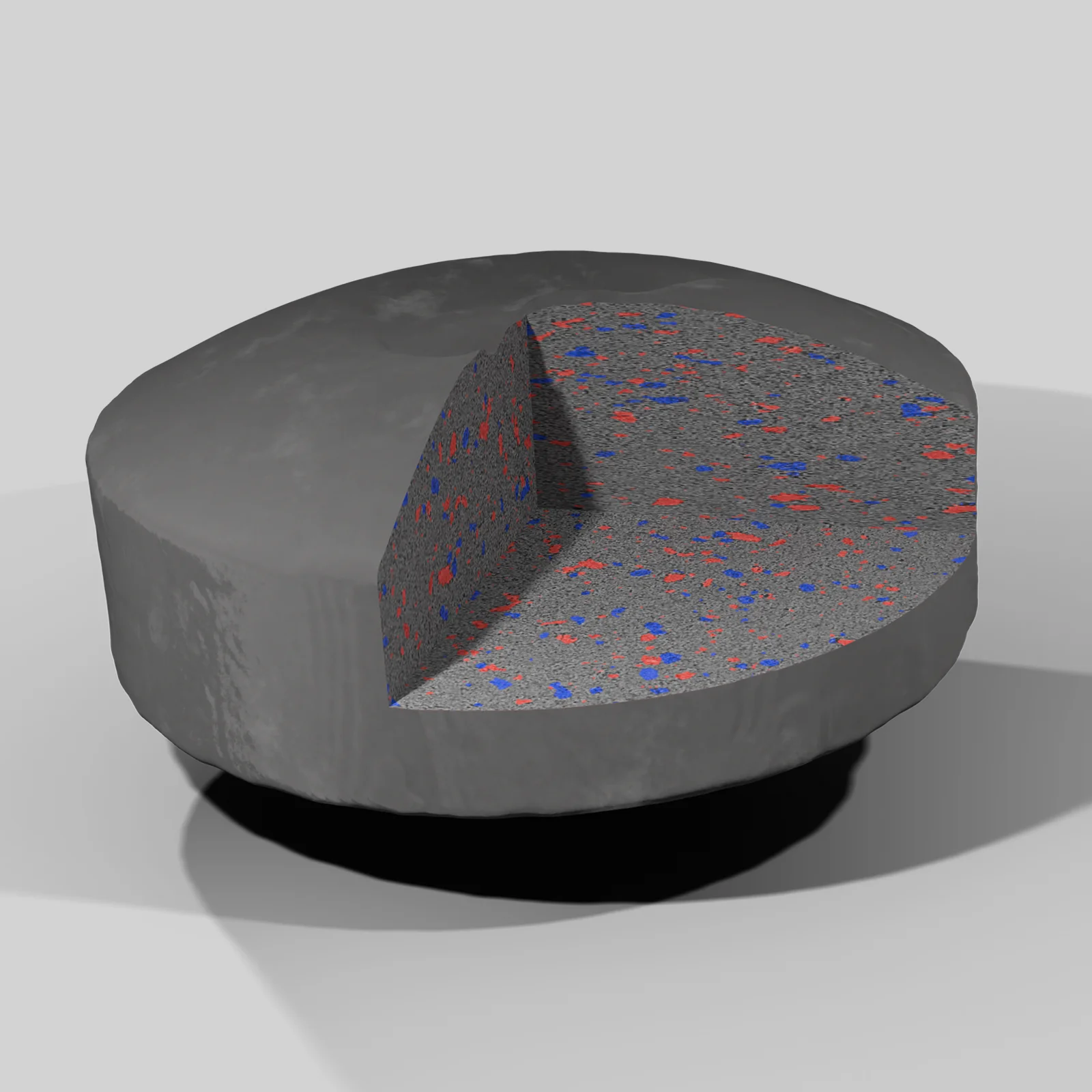

Historically within the pharmaceutical and biotech industries, X-ray micro-CT has mostly been applied for small-animal imaging. As the leader in digital transformation for drug products, we have expanded its application usage significantly, studying nearly all drug product dosage forms. The applications of X-ray micro-CT analysis for drug development are endless, the only limitation being the ease of studying liquid solutions and suspensions. Dosage forms we frequently study include tablets, capsules, powders, implants, topicals, and microspheres. Uniquely, XRCT enables true non-destructive and non-invasive inspection of microstructures within the final drug product. Example attributes include drug particle size, porosity, ingredient distribution, defects, coating thickness, and surface area. With these data, we often support the construction of data packages for ANDA and NDA filings.

Upon digital reconstruction of drug product microstructures with 3D XRCT, ingredient particles and porosity networks can be used for image-based simulation of mass transport phenomena. In silico assessment for dissolution, disintegration, sublimation resistance, and reconstitution can be performed directly from analyzed 3D XRCT datasets.

Formulations

Studied

Be Part of The Therapeutics Revolution

Revolutionize drug development with our AI-driven platform. Get started today.